Comprehensive Overview of Aluminum Alloy Casting Methods and Applications #

Aluminum alloy casting is a versatile manufacturing process where molten aluminum alloy is poured into molds to create parts with specific shapes and properties. Due to their lightweight, high strength, and excellent thermal conductivity, aluminum alloys are widely used across various industries.

Key Aluminum Alloy Casting Methods #

Sand Casting #

Sand casting, also known as sand mold casting, involves forming a cavity in a sand mold that matches the desired part shape. Molten aluminum alloy is poured into this mold, and after cooling, the casting is removed. This method offers significant flexibility, allowing for the production of parts in various shapes and sizes, and supports design modifications during the process. Sand casting is cost-effective for mold production and is suitable for both large and medium-sized parts, especially in low-volume or prototype production. However, sand molds have a shorter lifespan and require regular maintenance, which can increase costs and downtime. The process is slower and generally results in lower surface accuracy compared to gravity casting.

Gravity Casting (Die Casting) #

Gravity casting, also referred to as die casting or gravity die casting, utilizes gravity and sometimes pressure to fill a metal mold with molten aluminum alloy. The metal cools and solidifies quickly, resulting in high-precision parts with excellent dimensional control and surface finish. This method is efficient for large-scale production and is ideal for complex, integrated structures, reducing the need for assembly or welding. Gravity casting is best suited for smaller, intricate parts due to the higher cost and complexity of mold production and the need for specialized equipment. It is not typically used for very large castings.

Comparison Table: Sand Casting vs. Gravity Casting #

| Feature/Aspect | Sand Casting | Gravity Casting |

|---|---|---|

| Advantages | - High flexibility for complex shapes and large parts |

- Low mold cost and reusability

- Adaptable to various sizes and design changes

- Suitable for low-volume, diverse production and prototyping | - Excellent dimensional control for high-precision, complex parts

- High production efficiency for large quantities

- Enables integrated structures, reducing assembly

- Superior surface flatness, minimal post-processing | | Disadvantages | - Slower production speed

- Lower surface precision and flatness | - Higher mold production cost

- Requires significant equipment investment

- Not suitable for large castings |

Aluminum Alloy Material: A356 #

A356 is a lightweight aluminum alloy primarily composed of aluminum, silicon, and magnesium. Silicon and magnesium enhance its strength and corrosion resistance. Additional elements provide high toughness and fatigue resistance, making A356 suitable for demanding applications. It is easily machinable and can be heat-treated for increased strength and hardness. However, A356 is prone to oxidation at high temperatures, which can affect its appearance and performance, and it is more expensive than standard aluminum alloys. Its combination of strength and lightness makes it popular in industries such as semiconductors, electronics, and sports equipment. Typical uses include automotive engine blocks, rotors, and fan blades. Rong Feng primarily utilizes A356 for casting, with other materials available upon request and order volume.

Applications of Aluminum Alloy Casting #

- Automotive Industry: Used for engine parts, chassis, suspension, exhaust systems, and wheels, aluminum alloys contribute to lighter, more efficient vehicles.

- Aerospace Industry: Ideal for structural and engine components like flaps, propellers, and fuselage parts due to their strength-to-weight ratio.

- Electronics: Excellent thermal conductivity and corrosion resistance make aluminum alloys suitable for casings, enclosures, and heat sinks.

- Industrial Equipment: Pumps, valves, compressors, and mechanical parts benefit from the alloy’s strength and corrosion resistance.

- Sporting Equipment: Lightweight and durable, aluminum alloys are used in bicycles, golf clubs, boats, and camping gear.

- Construction Industry: Ductility and machinability allow for complex architectural designs, while corrosion resistance ensures longevity in outdoor environments.

Rong Feng’s Aluminum Casting Process #

Rong Feng’s technical team applies extensive experience and expertise to maintain a rigorous production process. Each stage—from mold making, casting, pouring, deburring, and sandblasting to final inspection—is carefully managed to ensure high-quality results. This commitment to quality supports both functional and aesthetic requirements, as seen in notable architectural projects.

Notable Project Examples #

- National Taichung Theater, Taiwan: Features reflective cast aluminum panels.

- Minsheng College Teaching Building, Taiwan Shih Chien University: Showcases perforated window walls.

With over 50 years of experience, Rong Feng has established a strong presence in both domestic and international markets, including Japan, Europe, and America. The company is recognized for its expertise and reliability in aluminum alloy casting.

Product Gallery #

Large Castings

Large Castings

Outdoor Equipment

Outdoor Equipment

Car Sand Cast Parts

Car Sand Cast Parts

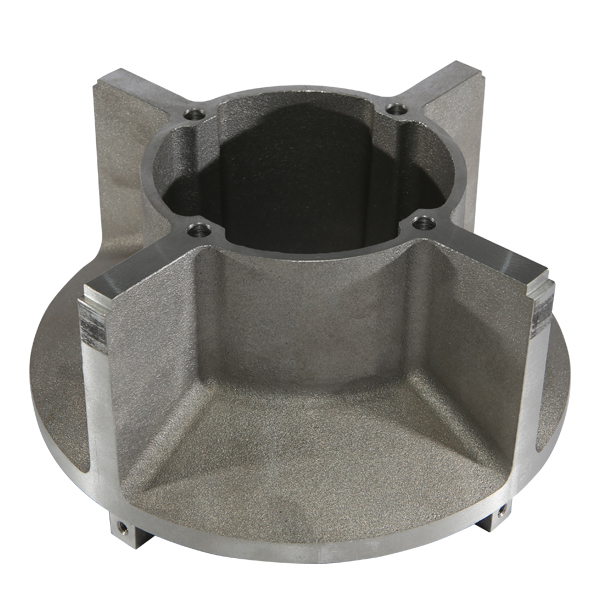

Cylinder Housing

Cylinder Housing

Machine Bases

Machine Bases

Architectural Cast Grille

Architectural Cast Grille

Car Cylinder

Car Cylinder

Electric Vehicle Pedal

Electric Vehicle Pedal

Precision Parts

Precision Parts

Gearbox Cover Casting

Gearbox Cover Casting

Sand Casting Machine Parts

Sand Casting Machine Parts

Lighting Fixture Sand Castings

Lighting Fixture Sand Castings

For further information or to discuss your aluminum alloy casting needs, please contact us.